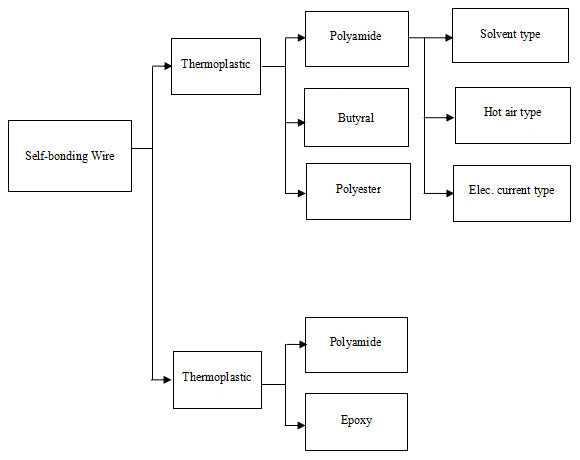

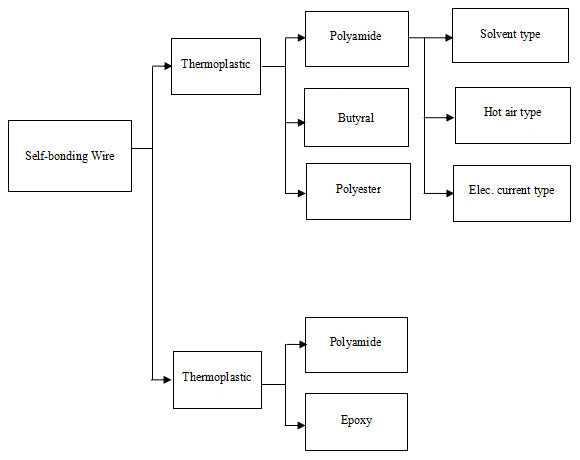

Self-bonding wire type

The heat-curable wire is heat-treated after being wound into a coil, and the film is solidified into a three-dimensional space.。

After winding,the coil is heated to change its thermosetting film into a thermally stable three-dimensioal structure.

Polyvinyl butyral

The self-adhesive layer is a self-adhesive line of polyvinyl butyral which is easy to process and is widely used in various applications. Such self-adhesive threads have two major advantages: low self-adhesive temperature required for coil bonding and processing conditions Broad。

Polyamide

Ronsen offers a variety of self-adhesive threads with polyamide as a self-adhesive layer. Polyamides have higher self-adhesive strength than other types of self-adhesive layers. In addition, some polyamide self-adhesive lines also have a higher re-softening temperature. However, some polyamide self-adhesive lines are hygroscopic and therefore difficult to use in hot and humid climates。

Polyester

The self-adhesive layer is a self-adhesive line of polyester which is easy to process, the wire has good bonding property and good wet resistance, and is widely used in ultrasonic implant processing。

Epoxy

The self-adhesive layer with self-adhesive layer is epoxy, which needs strong current heating during bonding. The coil has good adhesion and heat resistance and is used in the case of energized processing.

Other self-adhesive paint

In addition to the above self-adhesive layer, Ronsen also provides other types of self-adhesive layers. Most of the self-adhesive layers described below use modified polyamides such as aromatic polyamides to meet very high heat resistance requirements. This type of self-adhesive layer has a very high thermal stability, which makes it relatively difficult to process. On the other hand, improved heat resistance and higher re-softening temperatures are important considerations for certain product applications.